When developing Factories of the Future, security is also an important aspect. CyberFactory#1 will respond to this challenge by developing a set of safety and security capabilities. One of these capabilities is cyber resilience. Although the development work has not yet started, CyberFactory#1’s Finnish partners prepared and presented a Cyber Resilience Starting Point Demo in the project review at Oulu in January.

Figure 1 A part o fthe demo set-up

Resilient communications

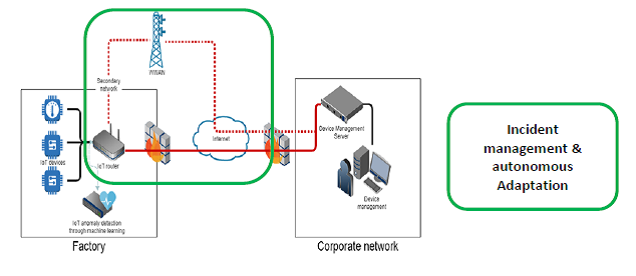

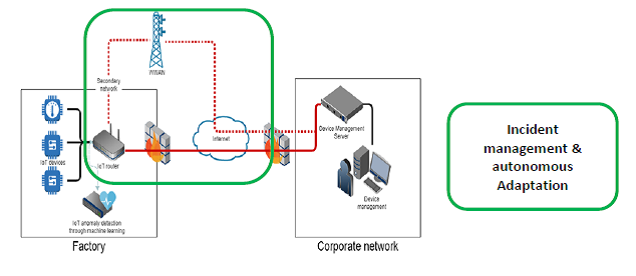

A key resilience function in FoF systems, including IIoT, is the ability to maintain constant connectivity to industrial control systems and other systems on a continuous basis. A single network may not provide sufficient reliability in critical manufacturin g systems. Therefore, in order to build resilient manufacturing systems, a seamless network failover is relevant. The scenario in Figure 2 demonstrates IIoT device network switching for resilient communications.

Figure 2 Demo scenario

Continuously up-to-date IIoT devices

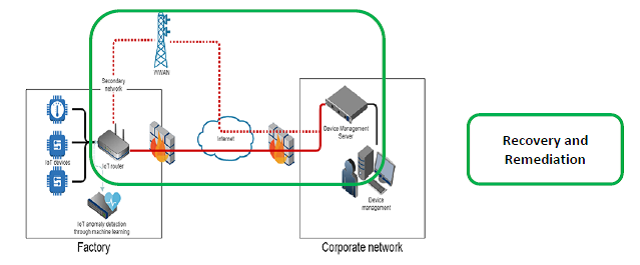

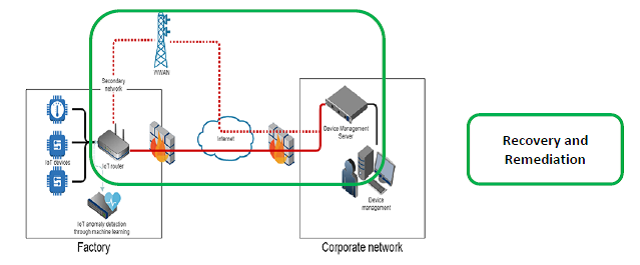

A common flaw in IIoT systems is the cumbersome or non-existent update management system. Administrator needs to be provided with insight on the current rate of deployment of up-to-date and outdated devices, and with capability to monitor the update progress in real-time, using the device management console dashboards. The scenario in Figure 3 demonstrates the use of standards based device management (LWM2M) and the standard mechanism for updating IIoT gateway remotely.

Figure 3 Demo scenario for standards based device management and remote updates

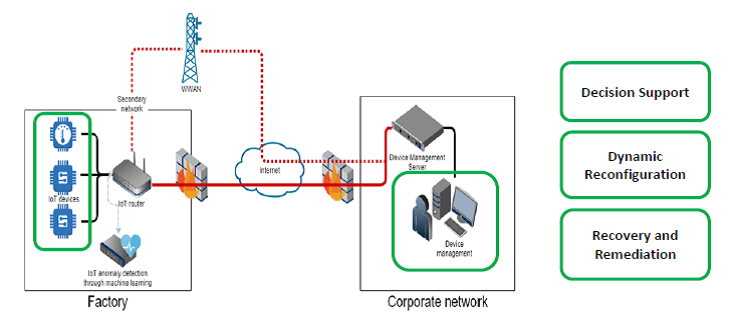

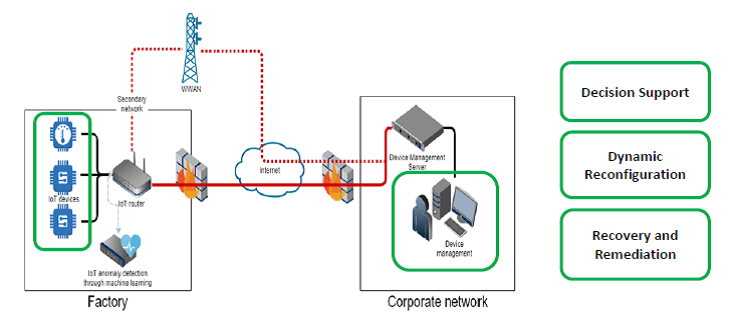

Dynamic reconfiguration of IIoT devices

Dynamic security policies in IIoT devices are an important enabler for resilience of IIoT systems. Based on IIoT device produced data (and changes in certain data points) the security policy of the IIoT device gets updated from the device management server. This scenario demonstrated how dynamic reconfiguration enables the recovery from incidents and disaster situations.

The demo was created in collaboration with Bittium, Netox, VTT and Rugged Tooling, using the knowledge of each partner to create a realistic environment. “It was great to able to contribute to creating the traffic needed, and test our sensor in the mutually created environment”, says Esa from Rugged Tooling. “Bittium SafeMove® Analytics was adapted to the demo in order to demonstrate the fleet of the IIoT devices, in order to detect the devices and required updates for cyber resilient operations. We were also able to connect the system seamlessly and wirelessly with the cloud connectivity provided by Netox”” clarified Björn from Bittium.

This Starting Point Demo was a great collaboration effort and a remarkable first step towards the Kick-off of Work Package 5: FoF dynamic risk management and resilience in April 2020.

Involved Partners: Bittium, Netox, Rugged Tooling, VTT Technical Research Centre of Finland